| Challenges in creating a complete dental prosthesis | Possible issues | Benefits of digital design |

|---|---|---|

| Uneven thickness | - Can lead to a sensation of heaviness or bulkiness for the patient

- Can affect the appearance of the full denture and create unwanted pressure points on the oral tissues |

- High precision and reproducibility ensure a uniform and consistent thickness throughout the prosthesis

- Digital adjustment of the thickness of different parts of the prosthesis is based on the specific needs of the patient |

| Inadequate adaptation and retention | - Can result in instability, unwanted movements or even difficulty in speaking and eating | - Digital adjustment of the shape and position of artificial teeth ensures increased stability and better retention of the full denture in the oral cavity

- Use of resins provides enhanced adherence to oral tissues |

| Overbite | - Can result in occlusal disorders

- Untreated overbite can cause jaw pain, chewing problems, headaches and even damage to adjacent teeth |

- Digital analysis and adjustment of occlusion achieve precise alignment of occlusal surfaces and ensure a balanced and functional bite

- Allows for visualization of contacts between artificial teeth and remaining natural teeth - Allows for occlusion tests prior to the final fabrication of the full denture |

By creating the full denture with powerful computer-aided design software, it is possible to:

With this advanced technology, you are involved in key stages of the design. Digital data can be instantly shared, enabling smooth and accurate communication. Additionally, you can provide detailed parameters and aesthetic specifications when it best suits you.

“To ensure effective collaborative work, we have developed TrakDesign. This online platform allows the user to see three-dimensional models of their cases, discuss specific cases with our technicians and comment on and approve the product before manufacturing. It also displays study models to compare elements,” explains Charles Desjardins, General Manager and Technical Expert at Lafond Desjardins.

The prototype is tested during the appointment to evaluate comfort, aesthetics and adaptation to the oral cavity. This step helps identify any adjustment and overbite issues to be corrected before manufacturing. By giving patients the opportunity to test the prototype, you can ensure that the final dull denture will meet their specific needs and provide optimal comfort.

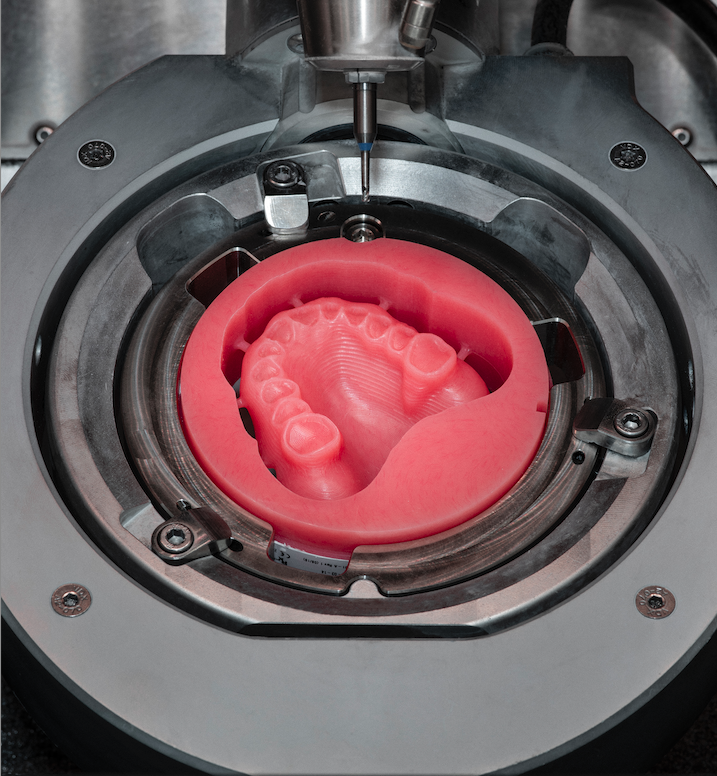

The prosthetic arches are milled from Ivotion Base discs by Ivoclar and Lucitone 199, high-quality resins that offer many advantages:

By choosing a digital product, you offer a removable complete denture that has stable occlusion, adequate thickness and superior retention. These important features contribute to a better quality of life and optimized chewing function. Learn more about this product and explore the detailed manufacturing process.