Our participative design and production process allows you to easily collaborate in key stages. This method ensures a highly precise dental prosthesis that meets the needs of the patient.

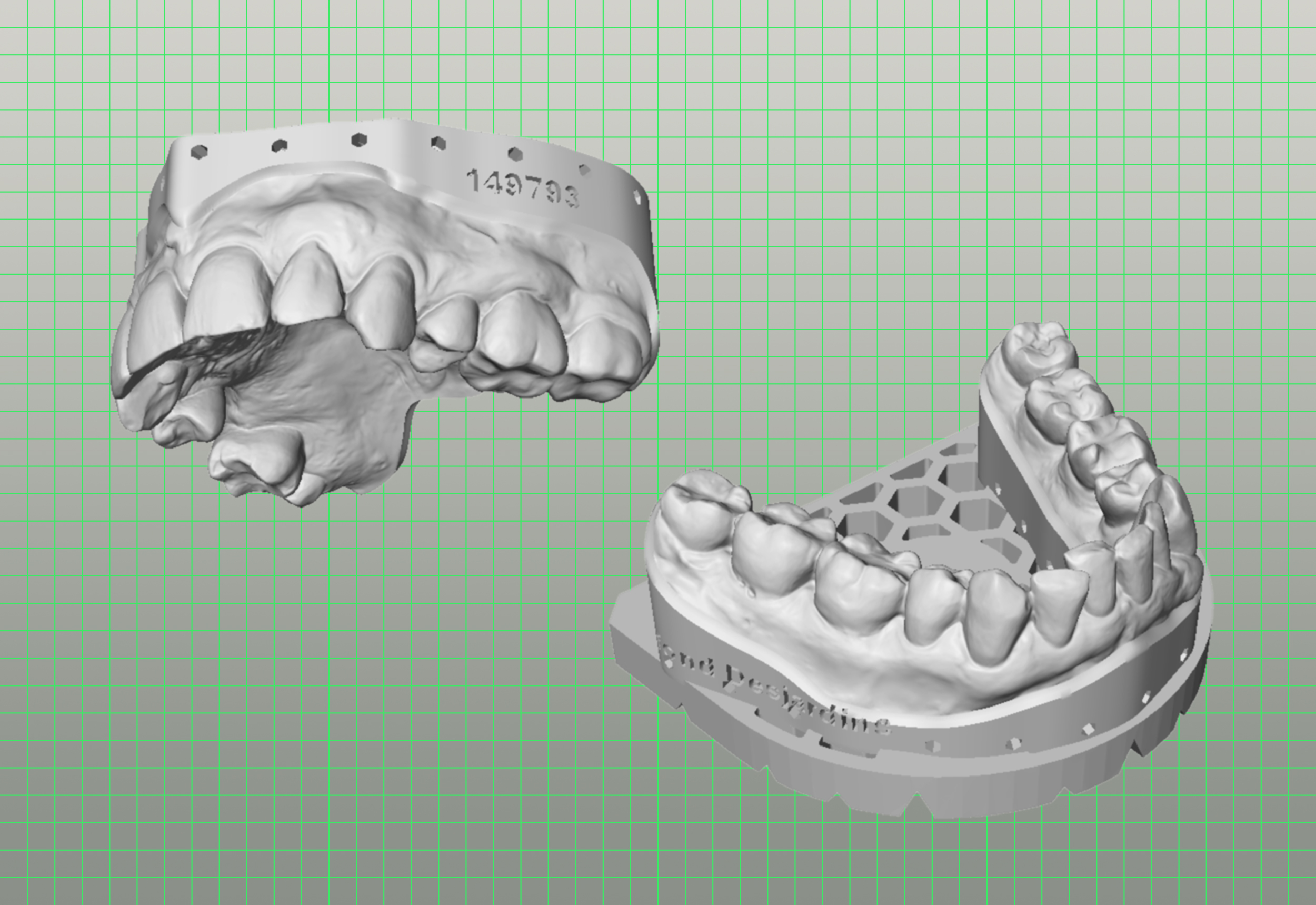

Both physical and digital intraoral impressions can be used to create a digital dental prosthesis. All types of files generated by an intraoral scanner are accepted.

With a Zirkonzahn scanner equipped with three high-definition cameras, the physical or digital impression is accurately imported into our computer-aided design software, creating a detailed representation of the patient’s mouth.

The intermaxillary tooth-size ratio, the Spee curve and the midline, canine and lip position are calculated using wax rims and baseplates.

A virtual Ivoclar Stratos articulator then defines the spatial position of the mandible in relation to the maxilla. These elements are scanned and the data is imported into 3D design software.

The removable dental prosthesis is modelled using powerful computer-aided design software. The teeth are selected based on the occlusal concept and desired morphology from a library of teeth.

This technology ensures a meticulous design:

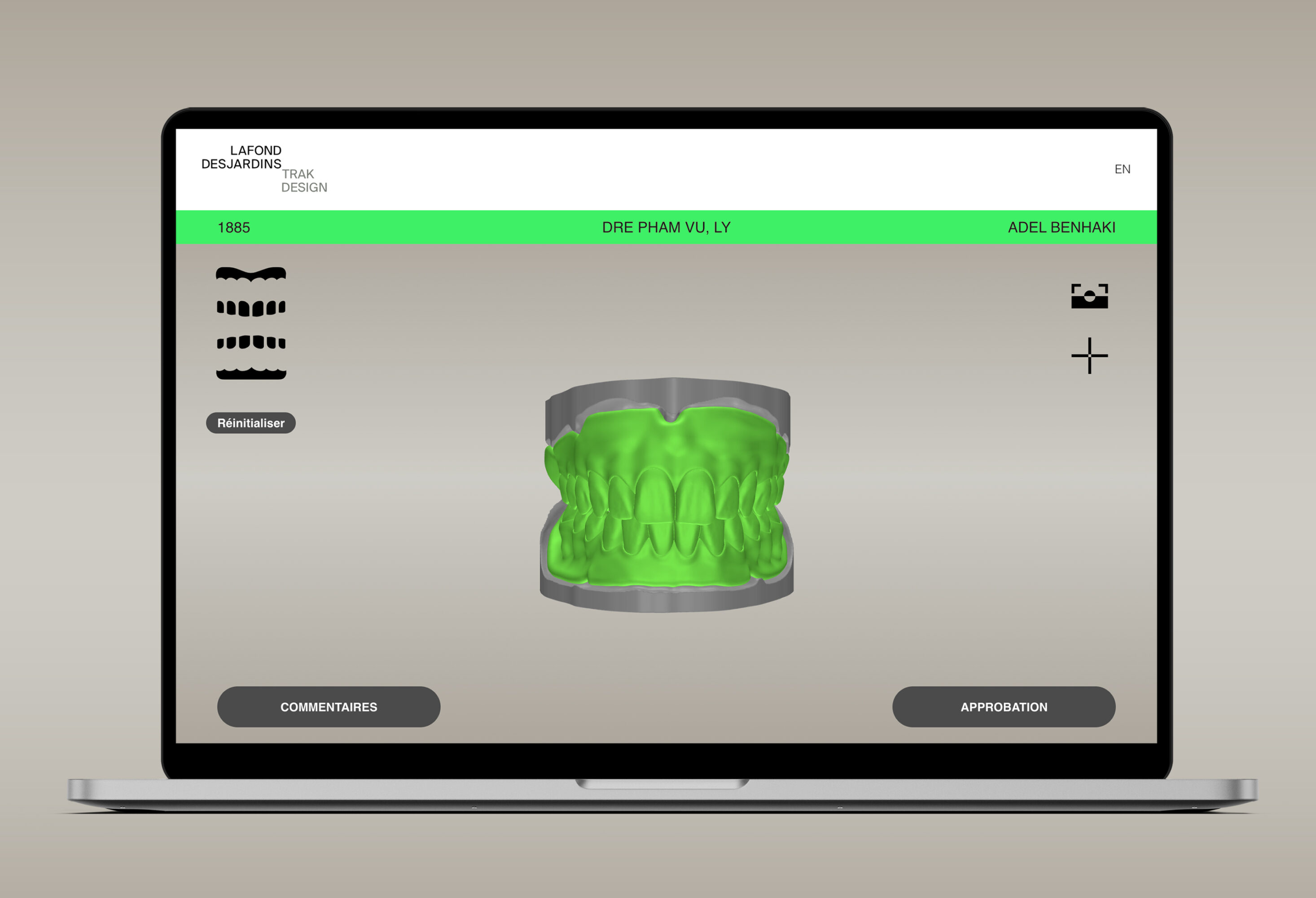

Visualize the three-dimensional modelling of the product before the prototype is created. The display of diagnostic, preoperative or temporary models, as well as the transparency filter, allows for a thorough comparison of the elements.

This important step significantly reduces manufacturing costs.

Printed with biocompatible resins, the prototype allows for validating the bite, occlusal functionality, tooth position and suction, allowing our technicians to make corrections before final production.

Adjustments are made through material addition and subtraction.

Our technicians use the corrected prototype to revise the case. A second 3D modelling is then accessible on the TrakDesign platform.

Comments regarding tooth positioning modifications can be added and are received instantly. Once the model is approved, the final printing is initiated.

The prosthetic arches are milled from Ivotion Base discs by Ivoclar, a high-quality resin that offers numerous advantages:

Cold bonding is preferred to maintain adaptation parameters. VITA VIONIC VIGO teeth, with their vibrant shapes and exceptional proportions, are bonded into the prosthetic bases, fitting perfectly within microns, thanks to the key-lock principle.

The low-viscosity, self-polymerizing bonding system is the preferred technique as it allows for:

The removable dental prosthesis is hand-polished until a natural-looking, glossy finish is obtained. The complete process and parameter control enable the polishing to be performed without the use of pumice stone. This technique ensures a scratch-free product with an impressive shine.