Our participative design and production process allows you to easily collaborate in key stages. This method ensures a highly precise dental prosthesis that meets the needs of the patient.

Both physical and digital intraoral impressions can be used to create a digital dental prosthesis. All types of files generated by an intraoral scanner are accepted.

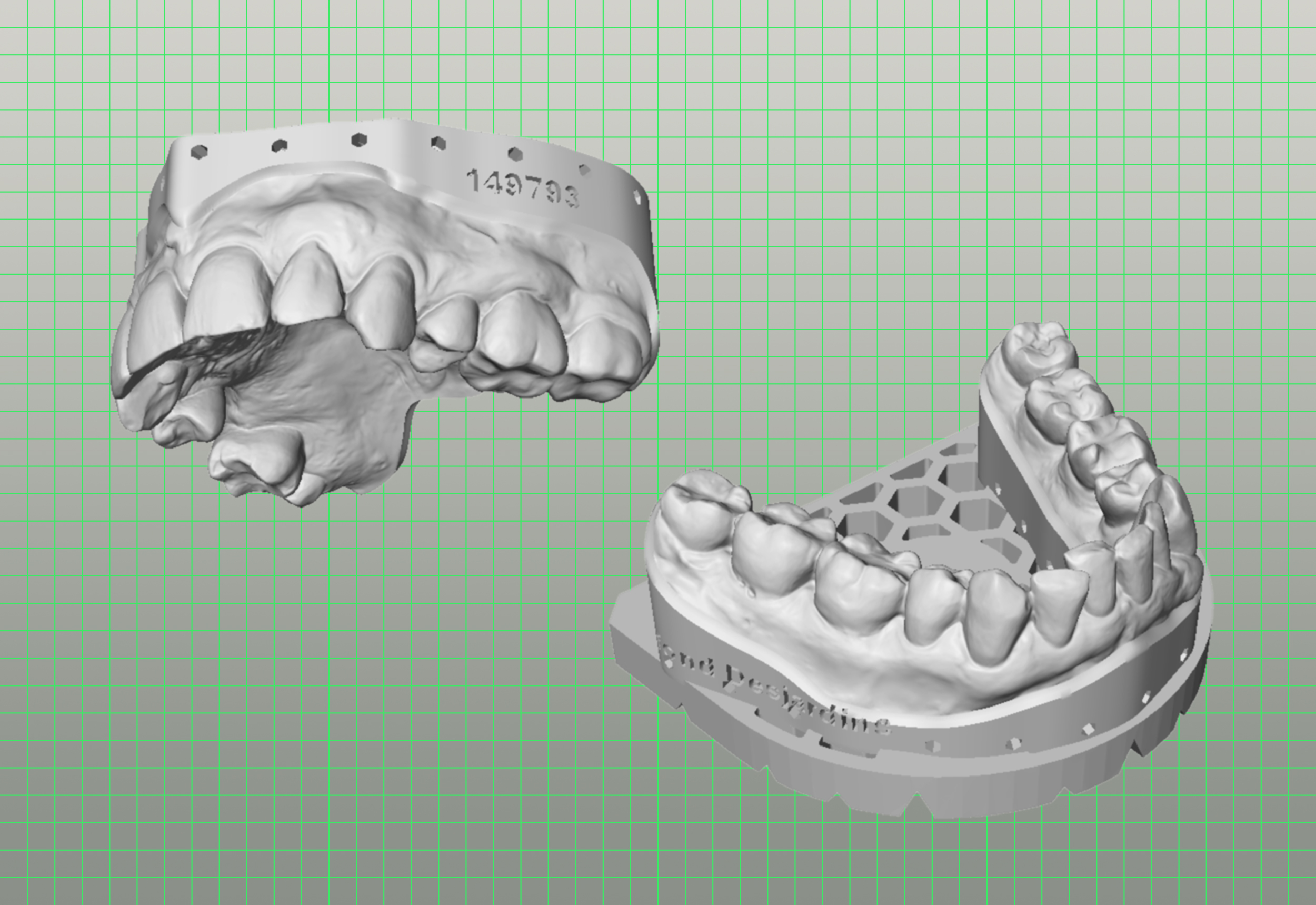

With a Zirkonzahn scanner equipped with three high-definition cameras, the physical or digital impression is accurately imported into our computer-aided design software, creating a detailed representation of the patient’s mouth.

The product is modelled using the patient’s dental model, which is perfectly reproduced using our powerful Zirkonzahn software.

For optimal results:

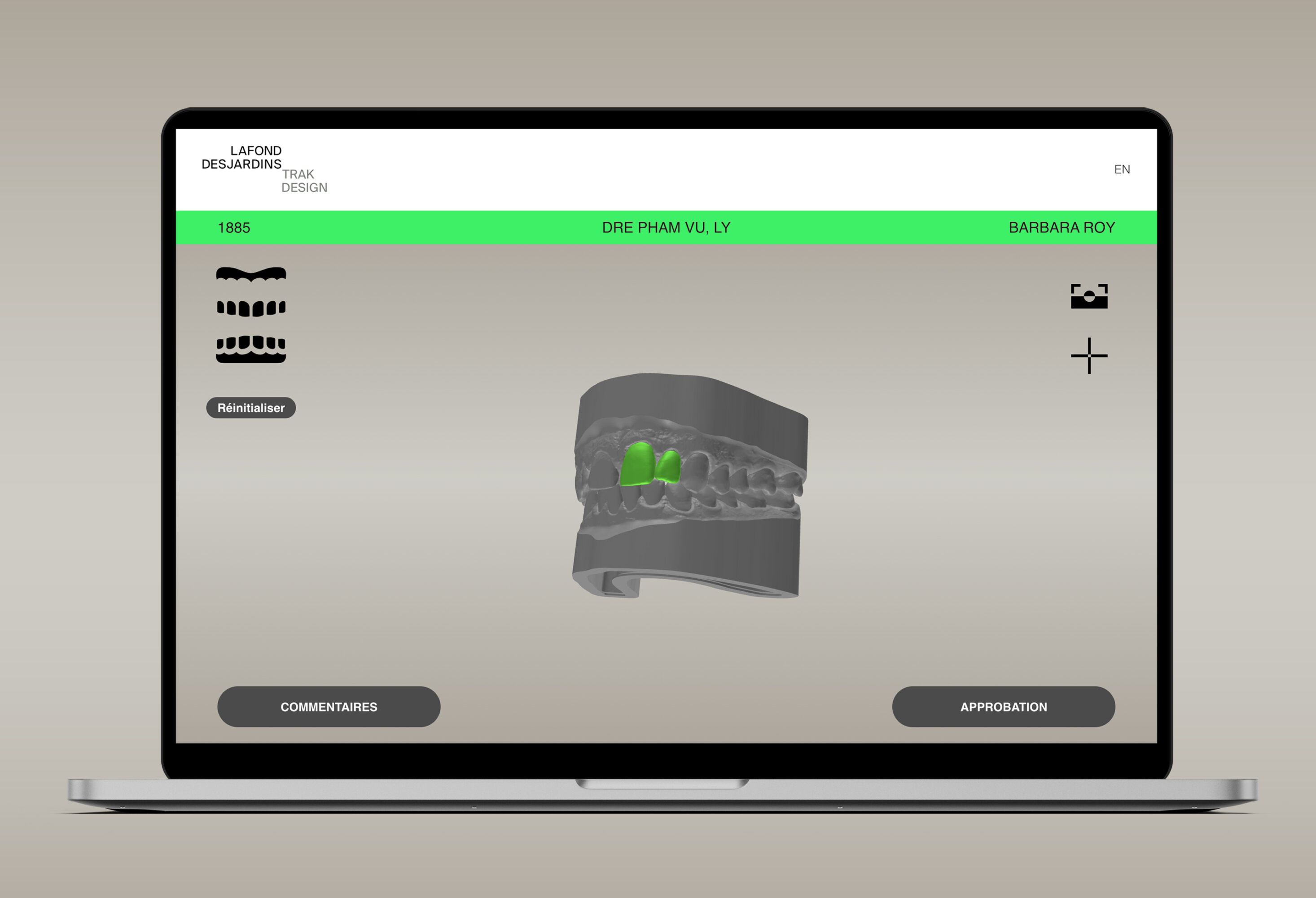

Using the TrakDesign platform, you can comment on and approve the 3D model.

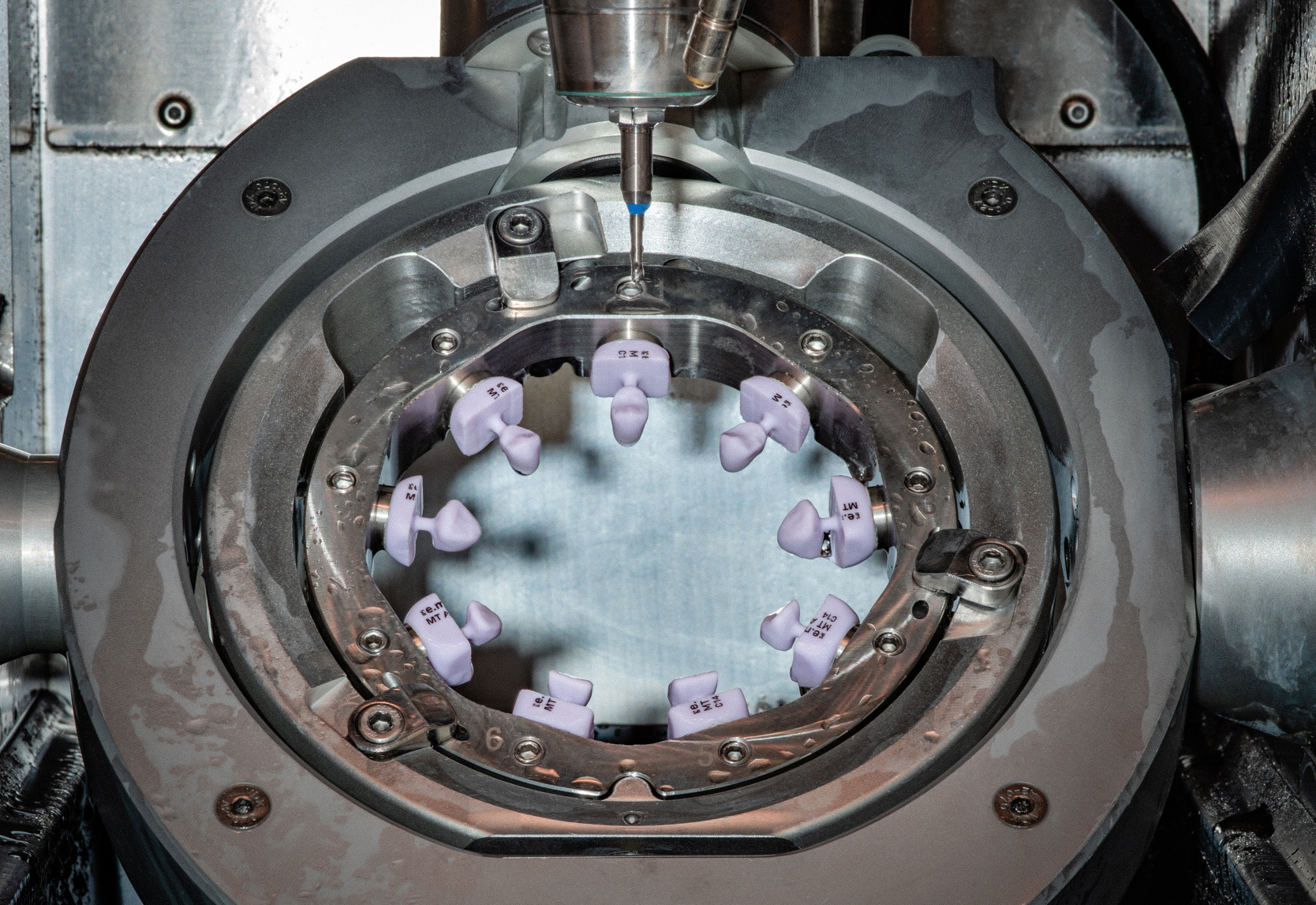

A computer-aided milling machine smoothly shapes the crown or bridge with precision. This passive production method ensures an aesthetic and biocompatible prosthesis with excellent mechanical strength.

For gold teeth, the structure is milled from a high gold alloy to provide a product with consistent mechanical density.

This type of ceramic allows for functional and aesthetic teeth that withstand bending and thermal shocks.

After the application of ceramic in successive layers, the base colour and shades are meticulously applied by hand, one by one, to reproduce the natural appearance of teeth.

The product is fitted to the 3D-printed dental model of the patient’s mouth.