Our participative design and production process allows you to easily collaborate in key stages. This method ensures a highly precise dental prosthesis that meets the needs of the patient.

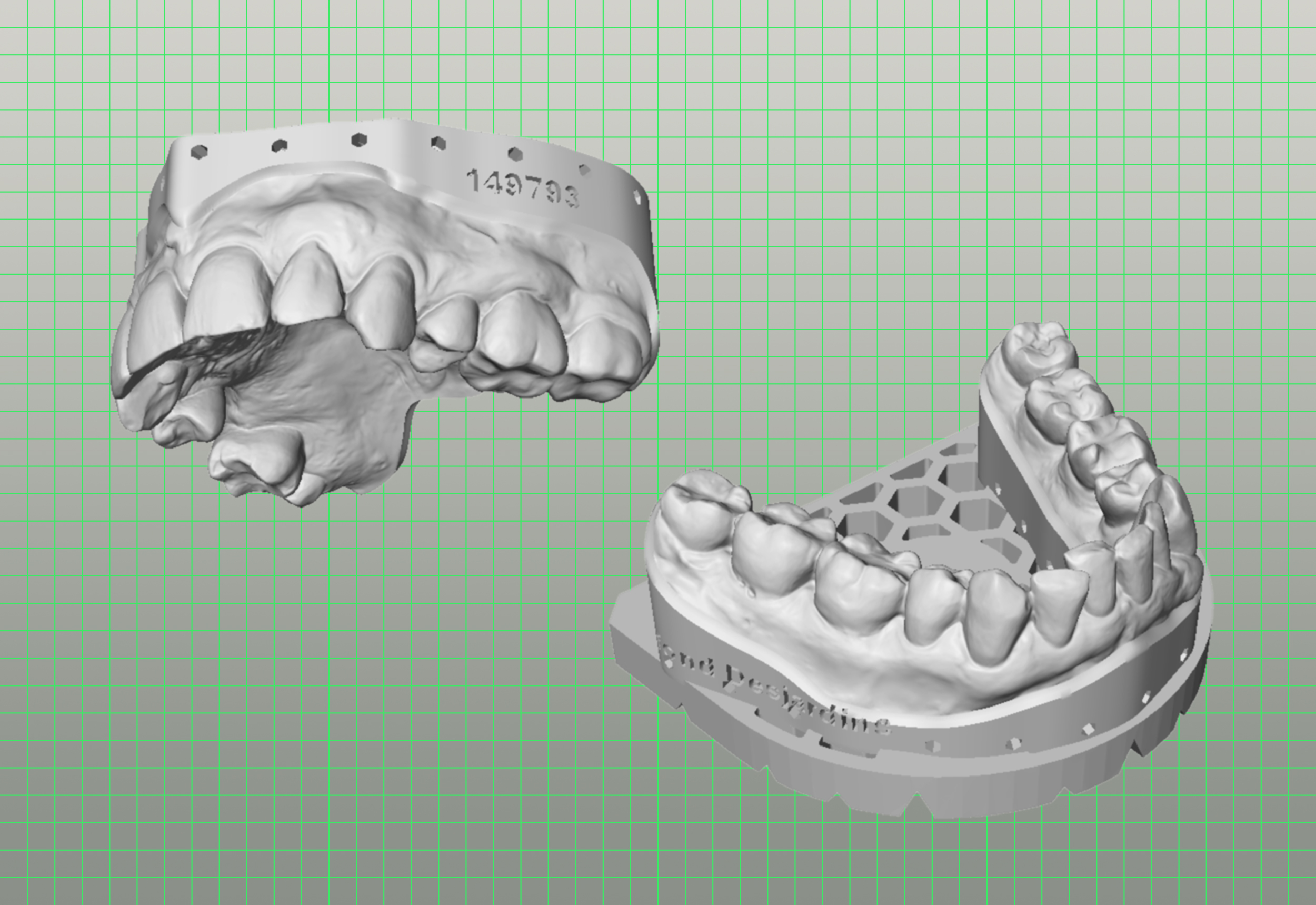

Both physical and digital intraoral impressions can be used to create a digital dental prosthesis. All types of files generated by an intraoral scanner are accepted.

With a Zirkonzahn scanner equipped with three high-definition cameras, the physical or digital impression is accurately imported into our computer-aided design software, creating a detailed representation of the patient’s mouth.

The nightguard is created using the dental model of the patient’s mouth, which is accurately replicated using advanced Zirkonzahn software.

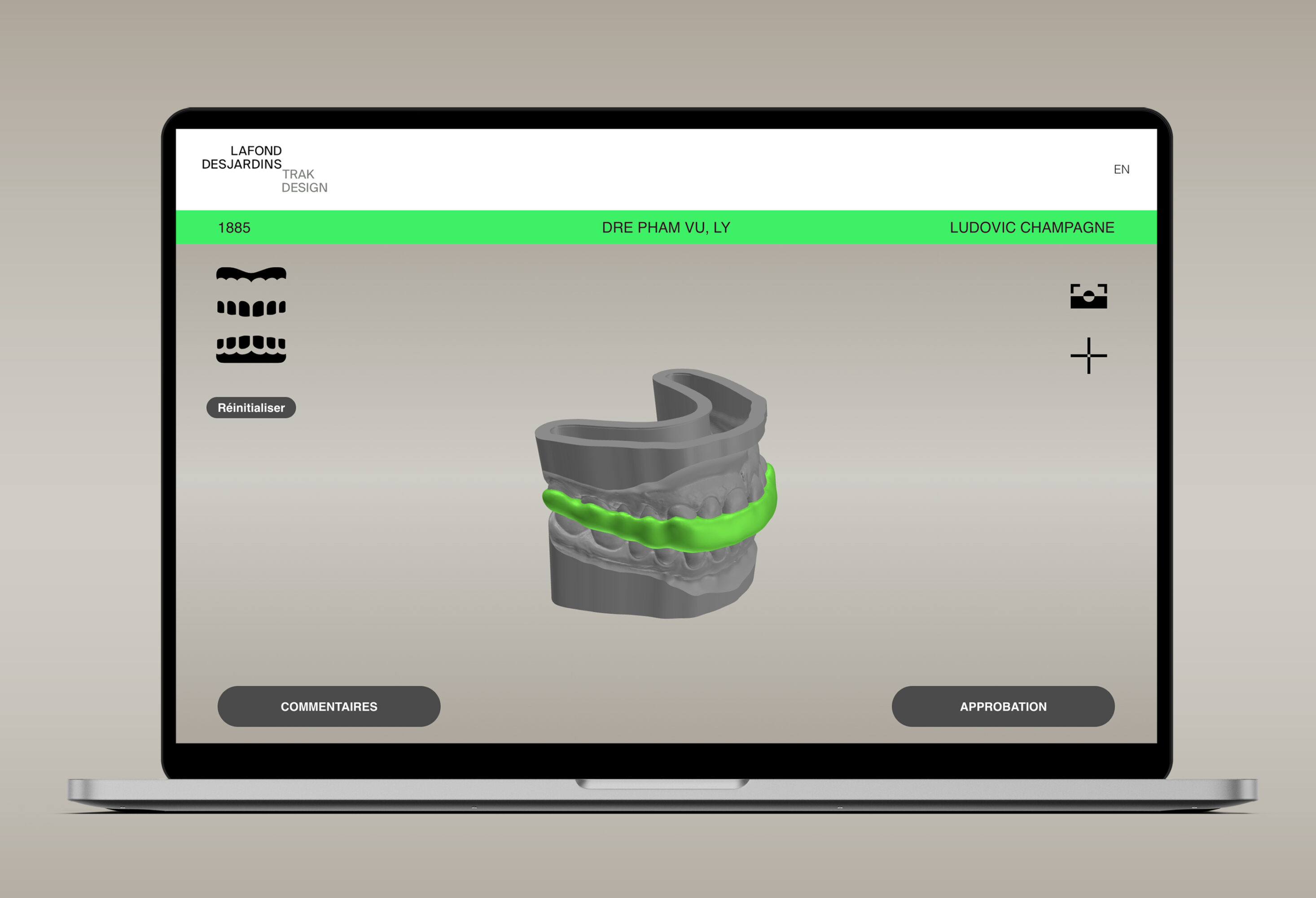

Computer-aided design facilitates:

The 3D model can be commented on and approved on the TrakDesign platform.

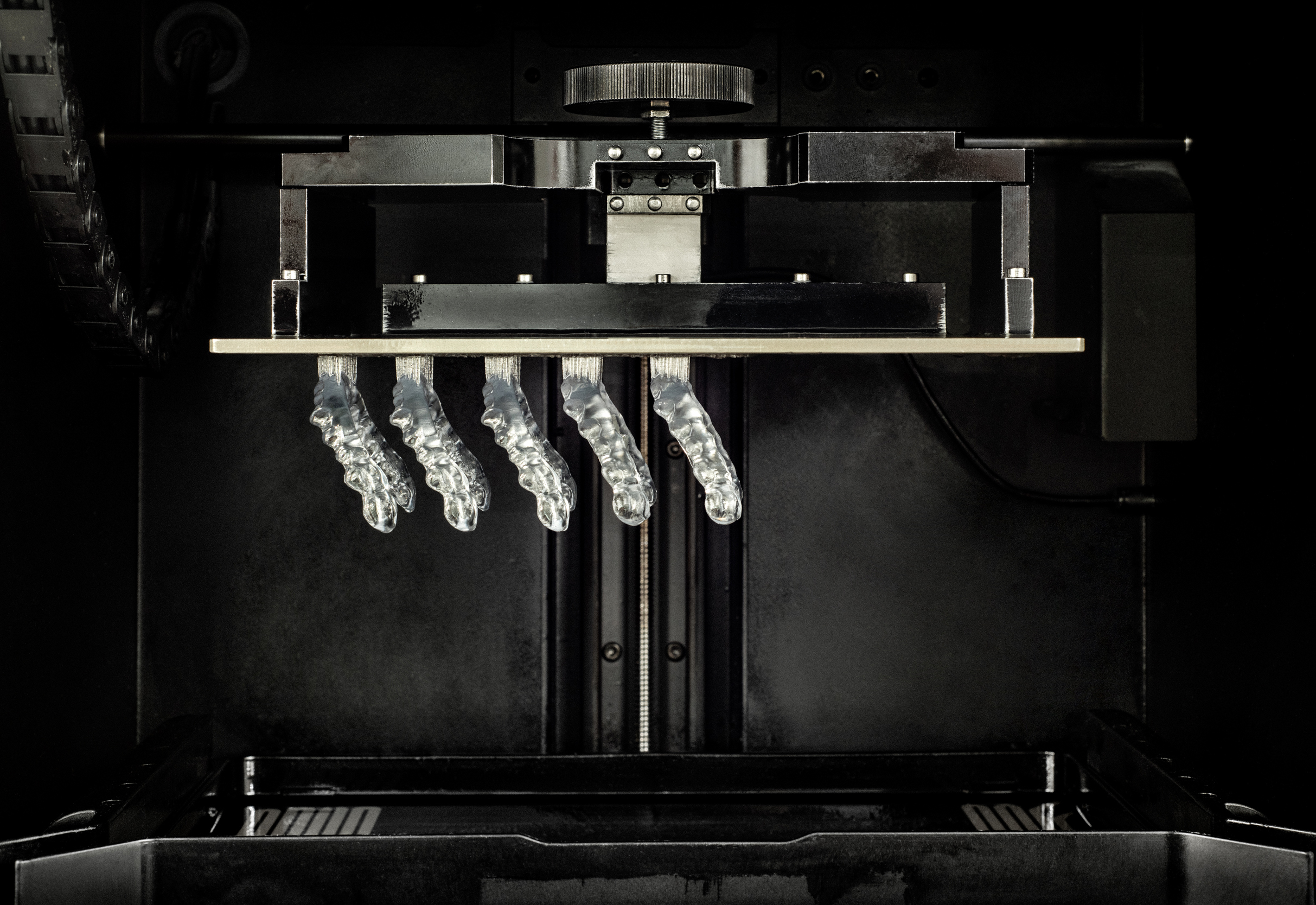

Printed with biocompatible materials and digital resins, the plate complies with regulations and international standards for medical devices.

The digitally fabricated nightguard, with neutral taste and stain-resistant properties, can be made using either rigid or thermo-flexible resin based on specific requirements.

The plate is adjusted using a calibrated Ivoclar Stratos articulator that accurately replicates lateral and protrusive movements. A manual polishing process without pumice stone is performed to achieve a remarkable glossy finish.

The digital nightguard is fitted on the patient’s printed dental model and the contact between the arches is validated.