When it comes to recommending an occlusal splint to your patients, you may sometimes have concerns about retention, comfort, durability and treatment adherence. The night guard offers many interesting features that encourage patients to wear it regularly.

The advantages of computer-aided design and computer-aided manufacturing (CAD/CAM)

1. Ensuring adequate thickness

The thickness of the occlusal splint plays a role in:

- Comfort and adaptation: a plate that is neither too thick nor too thin ensures optimal comfort.

- Alignment: balanced distribution of biting force and proper jaw alignment help avoid occlusal imbalances, excessive muscle tension and jaw-related problems.

- Protection: as the nightguard is used to protect teeth from bruxism, an appropriate thickness helps absorb the force exerted during chewing or clenching movements.

- Longevity: a nightguard with the right thickness ensures its increased lifespan.

By choosing a digital night guard, you provide your patients with a product that can be precisely adjusted to fit their dental structure and individual occlusion. Because the product is comfortable, the patient is more likely to follow the treatment plan strictly.

2. Increasing plate retention

Digital design allows for:

- precise adjustment of the occlusal splint’s contact surface with the teeth. An extended contact surface improves retention by creating a larger friction area between the night guard and the teeth, reducing slippage and promoting stability.

- effective reproduction of the patient’s jaw and tooth anatomy to ensure increased retention.

- easy detection and reduction of excessive contact or pressure points. By eliminating these points, patient comfort is improved and the movements of the night guard are reduced.

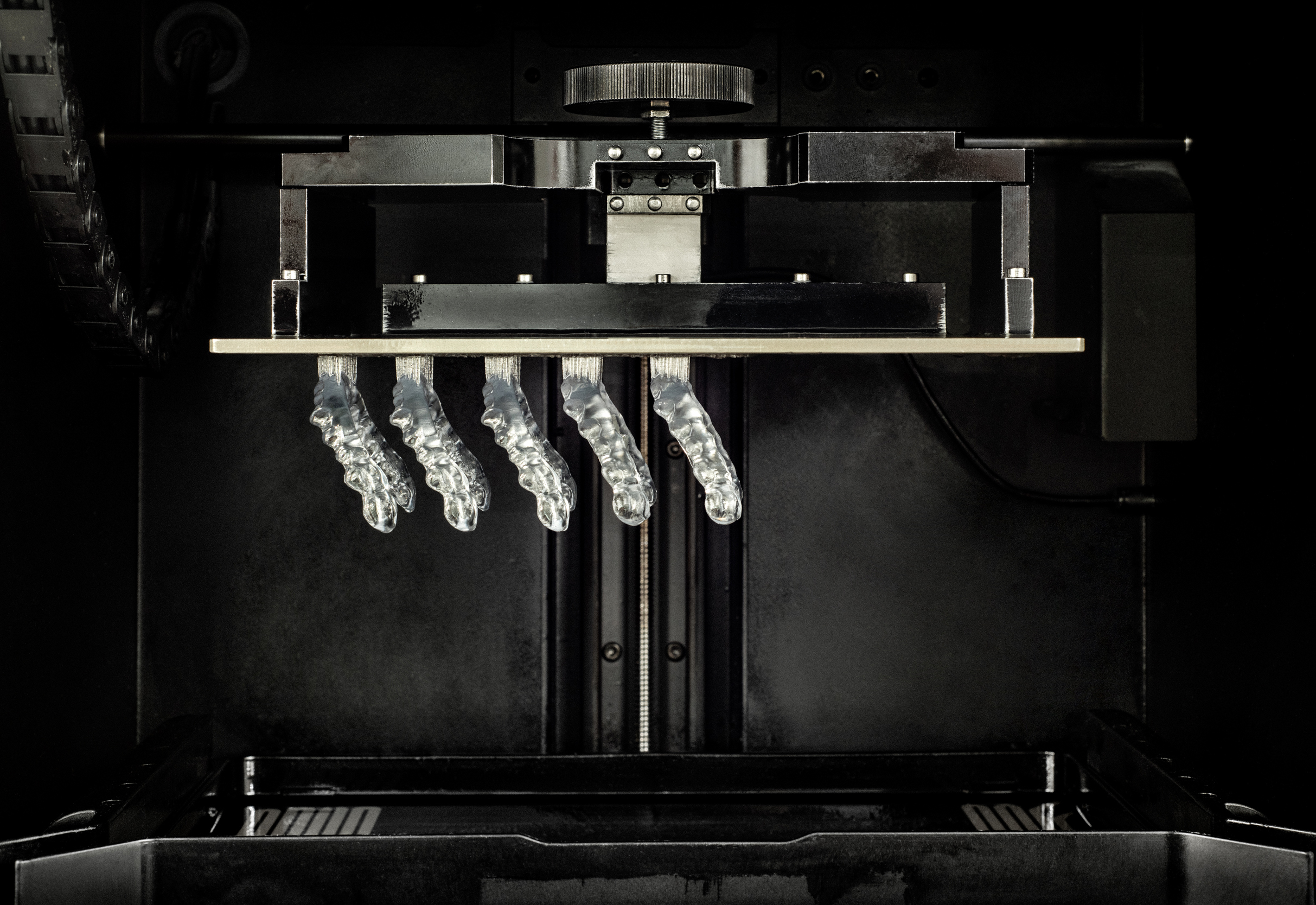

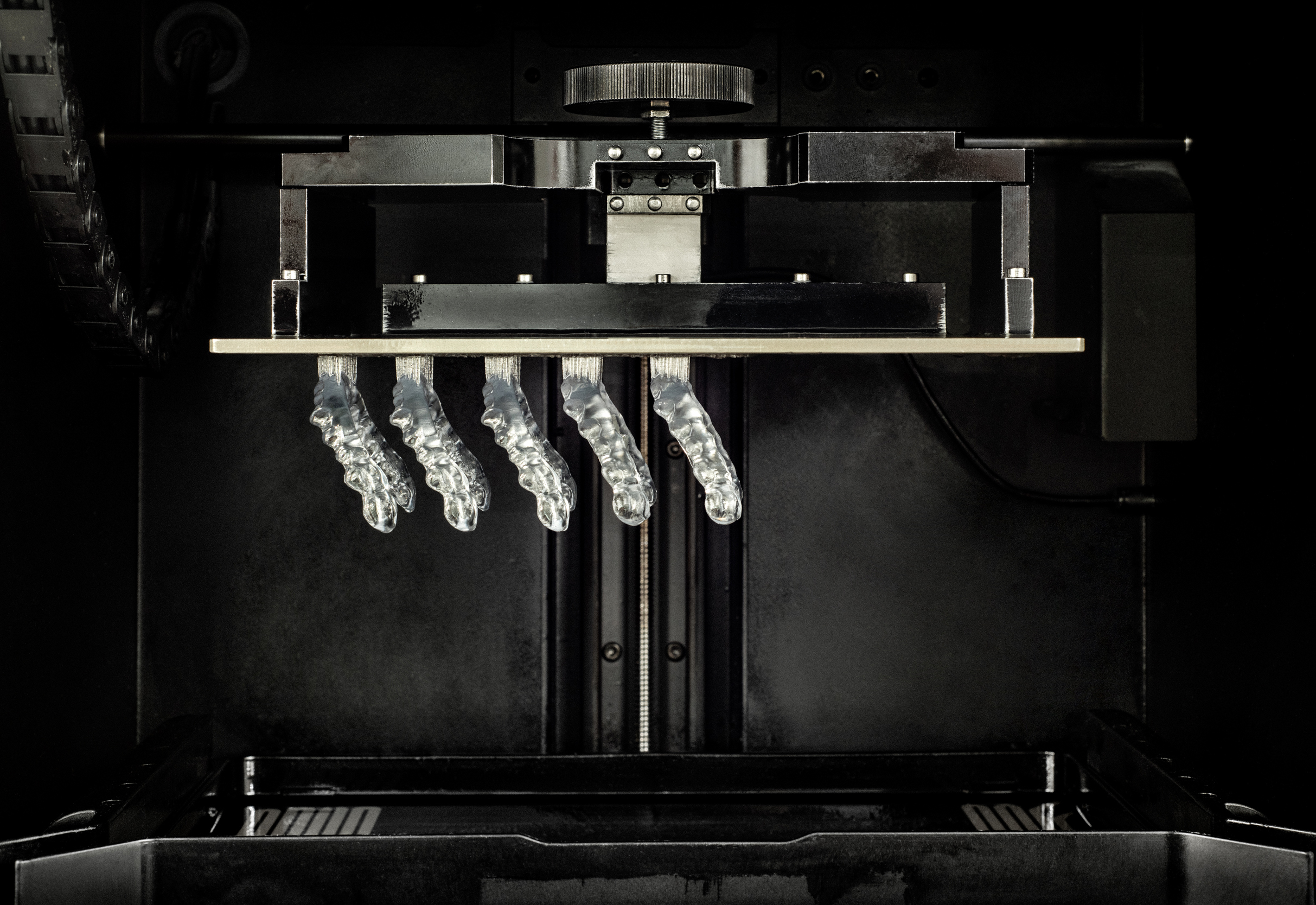

3. Using modern materials

The digital night guard is printed using state-of-the-art technology. The printing process allows for the use of digital dental resins that offer superior resistance to bending and breakage.

The Lafond Desjardins digital night guard:

- is produced with rigid or thermoflexible resin according to specific needs.

- is printed with biocompatible materials and digital resins.

- complies with regulations and international standards for medical devices.

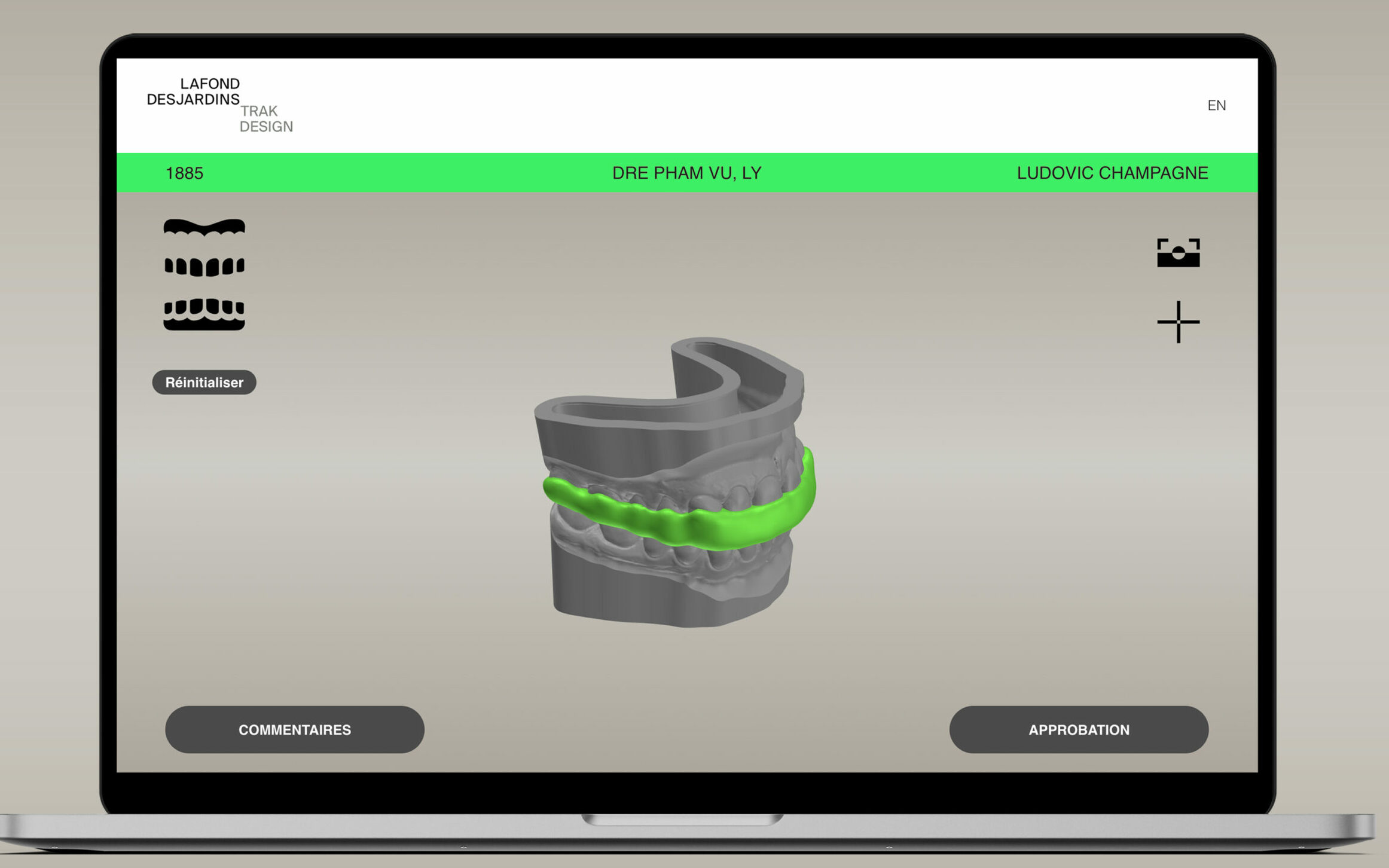

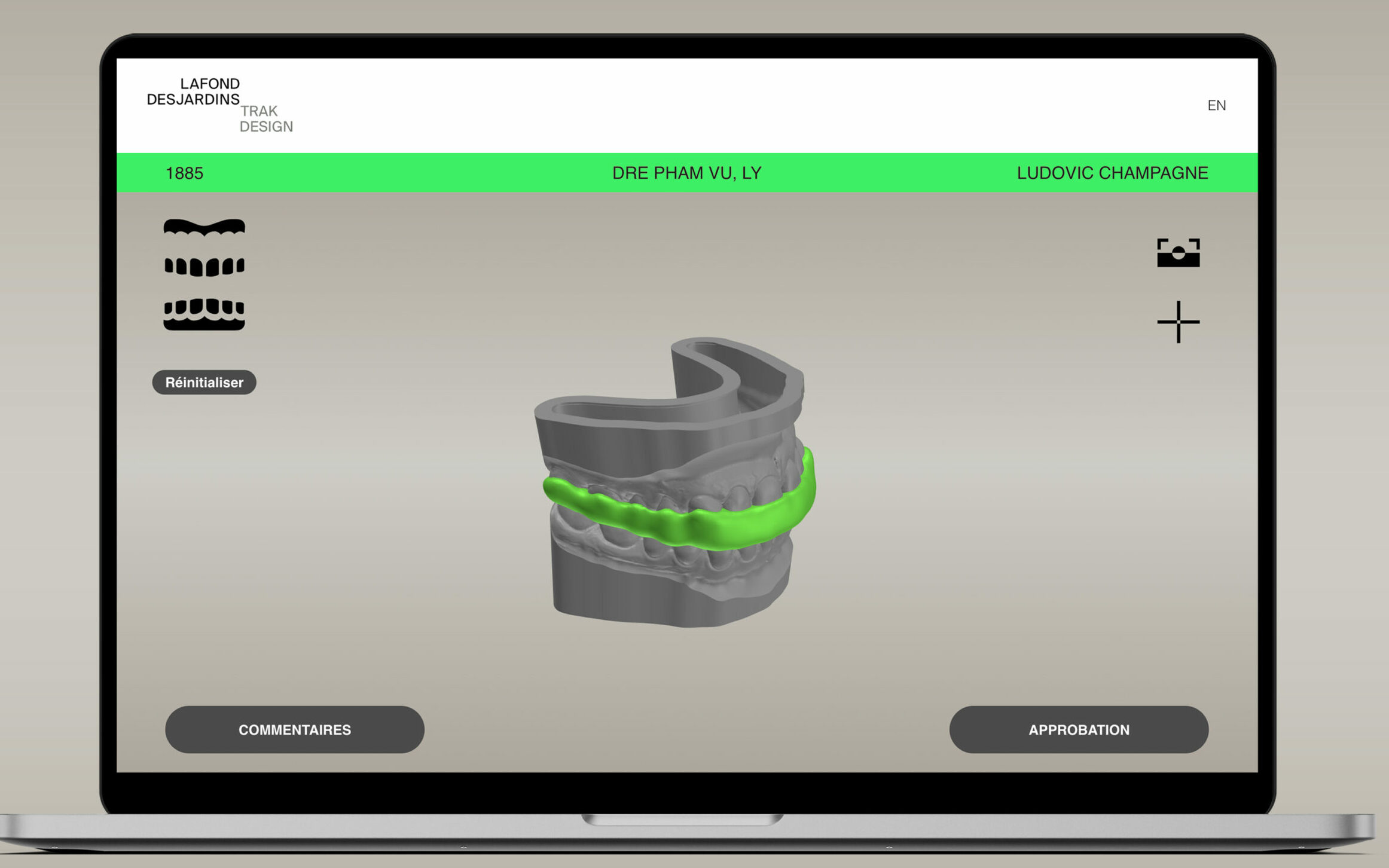

A collaborative platform to participate in key design stages

“Trak Design is an online platform that allows the user to visualize the 3D modelling of each of their cases and share their specific parameters and comments in real time with our team of specialists,” explains Charles Desjardins, General Manager and Technical Expert at Lafond Desjardins.

This innovative technological solution is offered with all our digital products.

A modern fabrication process for an effective treatment plan

By combining the precision of digital design and 3D printing, this type of occlusal plate allows you to offer your patients a personalized, durable and comfortable solution that often leads to better adherence to dental treatment. Learn more about this product and discover the design and production process in detail.